OERS (OER SERVICES LIMITED) is the subsea construction arm of the OER Group. We offer a wide range of subsea construction services, with key expertise in Pre/Post Trenching of Cables/Umbilicals & Pipelines, Cable & Umbilical Installation, Survey and Seabed mapping, Pipeline Pre-Commissioning, Pipeline Stabilization (including Free Span Rectification & Concrete Mattress Installation) and Shore Approach Construction.

OERS is highly focused on customer service and operational excellence. Our professional project team is well-resourced and highly experienced in delivering expertly engineered solutions for oil & gas construction projects.

We are driven by our commitment to promote and protect the health, safety, and wellness of our employees by providing a safe and incident- free workplace. We continuously strive to meet and exceed high standards of environmental responsibility and pollution prevention, while ensuring on-time project delivery.

Our experience, innovative equipment and strong resources enable us to deliver cost-effective and reliable subsea service solutions.

Construction Services

Pre/Post Trenching & Backfilling of Cables, Umbilicals & Pipelines

Our highly experienced team has trenched pipelines/cables in all corners of the world over the years. We have developed several innovative trenching systems to cater for specific site conditions found all around the world. Our systems are capable of trenching sandy soils, hard clays, and cemented soils. These systems have the ability to trench cables and pipelines of all types and sizes while operating in water deoths ranging from ultra-shallow to deep waters.

We utilise advanced technical instrumentation for controls and progress monitoring to provide commercially viable, efficient and precise solutions for both Pre and Post trenching operations.

Subsea Umbilicals, Cables, and Flowline Installation

OERS is backed by the OER Group's vast resources, and has strategic agreements with key suppliers in the industry. With these, OERS is well equipped to provide Engineering, Procurement, Installation and Construction support for subsea Umbilical, Cable & Flowline installations.

Pipeline Protection & Stabilization

OERS provides protection and stabilization of subsea pipelines and cables via the following methods:

- Pipeline Free Span Rectification

- Supply & Installation of Concrete Mattresses

- Rock Dumping

- Pipeline/Cable Crossings

Since stability requirements of subsea pipelines varies from project to project, there is no "one method fits all". Therefore, we offer the use of the above methods in isolation or combination. We can provide clients with custom built turnkey solutions with our inhouse resources.

Shore Approach Construction

Together with our experienced team and our specialist construction equipment, OERS offers the following specialist services:

- Site Preparation

- Pipe Pull and Shore Pull Operations

- Near-shore Pre/Post Trenching and Backfilling

- Site Re-Instatement

Pipeline Pre-Commissioning

OERS provides a complete range of subsea pipeline Pre-Commissioning services:

- Pipeline Cleaning

- Pipeline Guaging

- Pipeline Flooding

- Hydrotesting

- Leak Detection

- Dewatering

- Pipeline Drying

- Nitrogen Purging

Specialist Equipment

OERS has a wide range of equipment and specialist tools for projects, ranging from Pipeline/Cables/Umbilicals Trenching Systems, Shallow Water Barges, Jetting Pumps, to Hydraulic Winches. We also have access to chartered vessels that we use to mobilize equipment during various projects.

Support Barges

Shallow Water Trenching Support Pontoon Barge - Spider 1

The shallow water pontoon is used for Shore Approach Trenching on projects where the main support vessel is limited by its operational draft, and is unable to come close enough to shore. It is specially designed to be lifted offshore in fully loaded condition (65T).

The whole spread can be easily dismantled and containerised for convenient shipping worldwide.

| Dimensions: | 11.8m x 8m x 1.5m |

|---|---|

| Tare Weight: | 30T |

| Payload: | 35T |

| Operational Draft: | 0.8m - 1.2m |

Jetting Pumps

| Quantity: | 2 Units |

|---|---|

| Operating Pressure: | 225psi - 450 psi |

| Flow Rates: | Up to 6000 USGPM |

Trenching/Backfilling Machines

SJS - 1

| Overall Length: | 8.6m |

|---|---|

| Overall Width: | Variable 6m – 8m |

| Height: | 4.5m |

| Dry Weight: | 16T |

| Sub. Wt.: | Variable Floating – 12T |

| Pipe Sizes: | 6" + Conc. to 48" + Conc. |

| Type: | Pressurized Water Jetting & Water/Air Lift Eduction System |

| Soil Types: | Sand, Soft Mud/Clay to hard clays up to 100 kPa shear strength Optional: Hard clays of up to 220kPa shear strength. |

| Trenching Speed: | 60 – 200 m/hr (depending on Soil conditions) |

| Trench Depth: | Up to 3m Optional: Up to 6m in pipe riding mode. |

SJS - 2

| Overall Length: | 9.15m |

|---|---|

| Overall Width: | Variable 8.3m |

| Height: | 3.25m |

| Dry Weight: | 15T |

| Sub. Wt.: | Variable Floating – 10T |

| Pipe Sizes: | 6" + Conc. to 48" + Conc. |

| Type: | Pressurized Water Jetting & Water/Air Lift Eduction System |

| Soil Types: | Sand, Soft Mud/Clay to hard clays up to 100 kPa shear strength |

| Trenching Speed: | 60 – 200 m/hr (depending on Soil conditions) |

| Trench Depth: | Up to 3m |

SJS - 3

| Overall Length: | 9m |

|---|---|

| Overall Width: | 7m |

| Height: | 3m |

| Dry Weight: | 15T |

| Sub. Wt.: | Variable Floating – 10T |

| Pipe Sizes: | 6" + Conc. to 48" + Conc. |

| Type: | Pressurized Water Jetting & Water/Air Lift Eduction System |

| Soil Types: | Sand, Soft Mud/Clay to hard clays up to 100 kPa shear strength |

| Trenching Speed: | 60 – 200 m/hr (depending on Soil conditions) |

| Trench Depth: | Up to 3m |

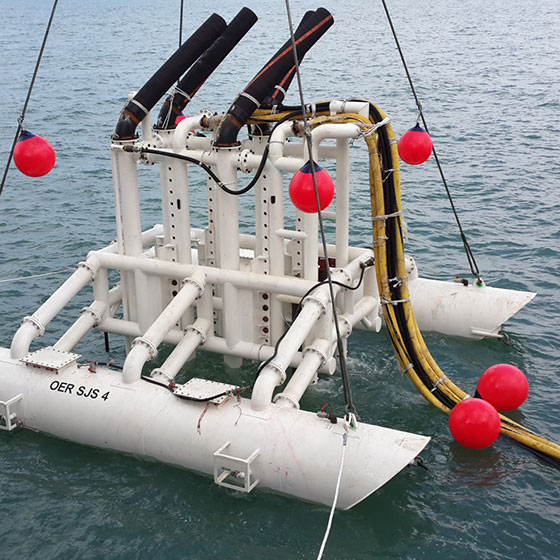

SJS - 4

| Overall Length: | 8.6m |

|---|---|

| Overall Width: | Variable 8.15m to 9m |

| Height: | 6.1m |

| Dry Weight: | 16T |

| Sub. Wt.: | Variable Floating – 12T |

| Pipe Sizes: | 6" + Conc. to 48" + Conc. |

| Type: | Pressurized Water Jetting & Water/Air Lift Eduction System |

| Soil Types: | Sand, Soft Mud/Clay to hard clays up to 220 kPa shear strength |

| Trenching Speed: | 60 – 200 m/hr (depending on Soil conditions) |

| Trench Depth: | Up to 3m Optional: Up to 4m |

Winches

OERS 35T Hydraulic Tow Winch

| Manufacturer: | Promoter Singapore |

|---|---|

| Model: | PE - 35 - M04/020 |

| Dimensions: | 2.2m x 2.2m x 1.8m |

| Tow Wire: | 22mm x 2000m (maximum) |

Project Credentials

The members of OERS project team have completed over hundred Pipelines, Cables and Umbilicals Installation and Trenching projects.

2014

PERTAMINA - GG1 - Field Development Project - Indonesia (Current)

OERS' scope of work consists of post trenching 18 kms of a 12" pipeline, including 2 km of shore approach trenching.

PEMEX - SINAN - 16" Pipeline Installation Project

This project involved post trenching of 9.4 kms of the 16" inter platform pipeline in Mexico.

BRUNEI SHELL PETROLEUM - 8" Pipeline Replacement Project (PRP-2)

OERS' scope of work consisted of post trenching of 8" pipeline shore approach. The project was completed using OERS' trenching machines SJS - 3 and the SPIDER - 1 barge.

2013

PEMEX LINE 5 - 36" Pipeline Installation Project

As part of the project, OERS' Scope of work consisted of post trenching over 30 kms of the 36" pipeline, while following Pemex's strict Upheaval Buckling Prevention Criteria. OERS' trenching machine SJS -1 was used to complete the project.

PTTEP-MOGE-ZAWTIKA 28" Pipeline Installation Project (Myanmar)

The project involved the following operations:

- Pre-Trenching For Shore Pull

- Shore Pull Operations

- Post Trenching of Shore Approach

- Installation of Concrete Mattresses